Precision casting refers to a technology to get precisely sized castings. Compared to traditional sand casting, the finished parts gained from precision casting has more smooth surfaces, lower tolerances and thinner walls. It includes Investment casting, Ceramic mold casting, Metal mold casting, Pressure casting and Lost foam casting and Investment casting is common used in casting industry.

Investment casting, also called lost-wax casting, makes parts from molten metal, usually stainless-steel alloys, brass, aluminum, and carbon steel.

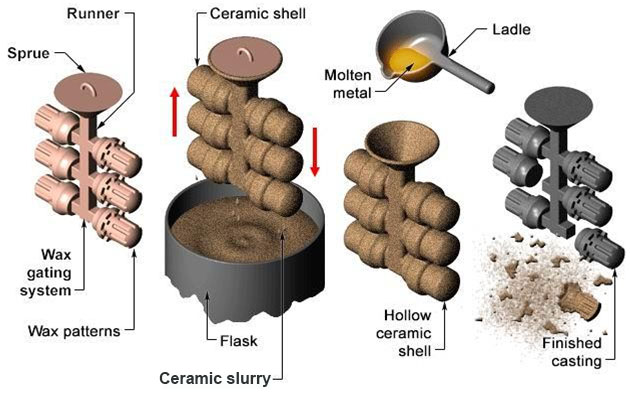

The first step in the process is to create a metal mold, and then fill it with hot wax and build a wax version of the final product. Second step, to cast several parts at once, several wax patterns can be assembled into a tree with wax runners and sprues carefully connecting them. Next step, the “tree” is then repeatedly dipped in a slurry and coated with layers’ of sand that hardens when it dries and we call it “Shell”. Then the shells are heated to remove the wax. The wax in the sprues and gates also flows out of the tree and forms tubes and pipelines for molten metal to follow and completely fill the mold. Last step, molten metal is poured into the now-empty mold and left to solidify. At last,the shell is destroyed to final post processings.

Investment casting process as attached......

Contact: StaroCasting

Phone: 0086-13851925018

E-mail: info@starocasting.com

Whatsapp:0086-13851925018

Add: Luoyang industry zone, Changzhou, China